OUR HISTORY

For seventy years, Ilpa has been innovating and adapting to market needs with technical and technological solutions constantly in mind.

ILPA

Innovative Formwork Panels

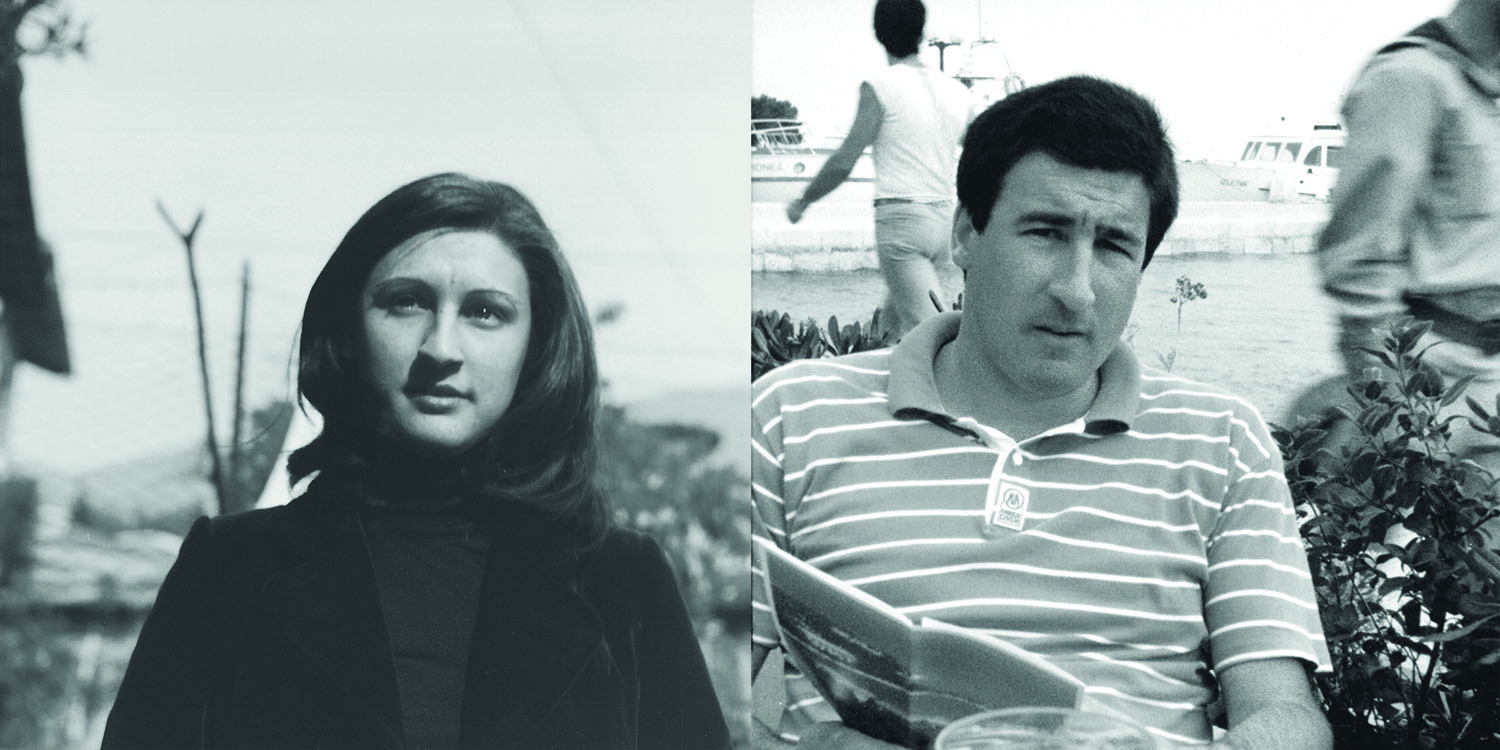

FOUNDER

Evaristo Pasotti (1920-1996)

1948

Birth of the Falegnameria Pasotti

1955

Start of production of wooden houses

1960

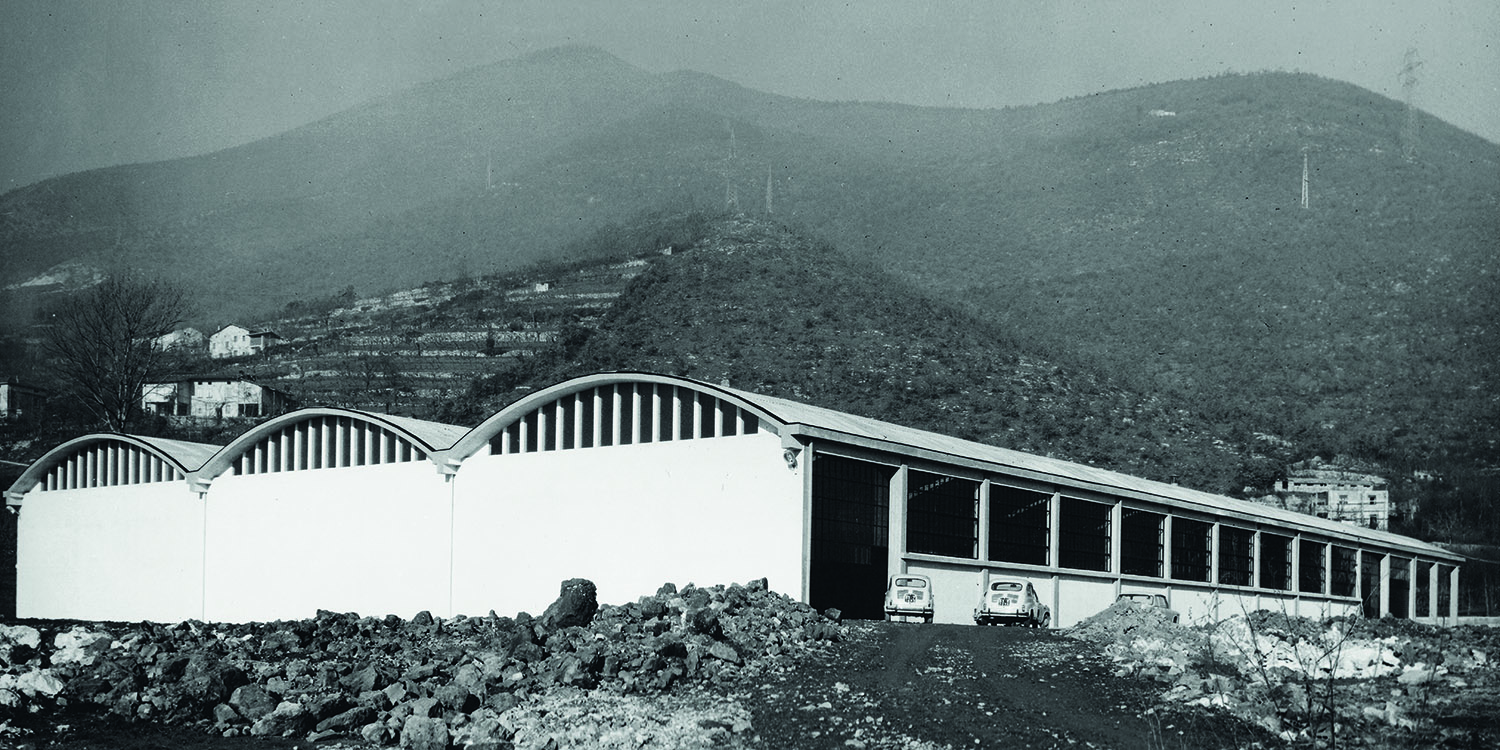

New production site

1962

Start of blockboard production

1974

The second generation joined the company

1976

First Lastron patent for prefinished wooden floors

1978

Start of formwork production

1994

Strato-Stock® patent

Innovative proposal to the formwork sector

2004

BAUMA 2004 - Xlife patent

The first ILPA patent shared with our partner

2017

Pur-Stock® patent

New innovative proposal to the formwork sector

2019

ILPA Engineering creation

2020

The third generation joined the company

2022

BAUMA 2022

PERI presents new ROBU B panel

2023

New additional warehouse

1948-2018

We have been innovating for seventy years.

OUR WORK

A mix of our own skills and those of our partners, which enable us to meet the demands of the market. We are a small, dynamic, and flexible company and intend to remain as such. For many years now, we have established a working network with industrial groups, as well as research and development institutes. We believe in the strength of partnerships, which guarantee long term solidity, as well as instruments, resources, and technology transfer between different fields. We have numerous joint patents in common and produce semi-finished and finished products exclusively.

Our plant in Nave

OUR VISION

We believe that joint research and development agreements with the major industry players in this field are an effective way of meeting many unmet demands in the market. We advocate for technological transfer between different sectors of the market. We strive to continue as we started, developing increasingly better solutions in the field of composite panels for the building industry.

INVENTIONS

We believe we are among the pioneering companies that have best contributed to the innovation of standard formwork panels. At the beginning of the 90s we were the first to patent the polyolefin based plastic overlay and utilize it on a wooden panel. This idea, which seemed apparently simple, proved to be successful over the years, succeeding in further enhancing the positive features offered by wood and, at the same time, limiting its negative shortcomings. Currently, we are testing a further edge protection for the formwork panel in order to improve sealing and consequently increase panel longevity.

MODUS OPERANDI

The persistent innovation created by ILPA, is the result of traditional internal research, from typical Italian inventiveness and the transfer of innovation from other technological sectors, with the support of our partners. From this approach our motto was born: STRONGER TOGETHER.

Traceability

All STRATO-STOCK® panel bundles have an identification label on which the production code and the barcode are shown, which allow for orderly and swift inventory management.

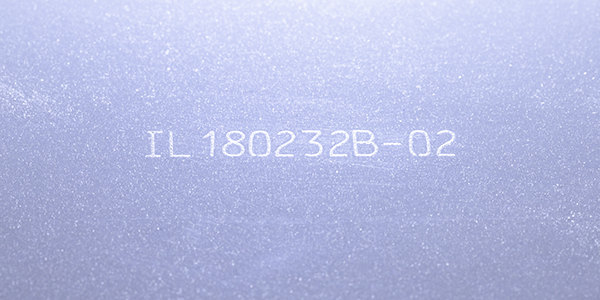

Laser engraving

All STRATO-STOCK® panels have a laser engraved tracking number on one side of the plastic overlay. This method guarantees maximum traceability for each panel, both for us and our customers.

RFID (radio frequency identification) Integration

Upon request, it is possible to insert RFID labels into each panel. The microchipping process is a sophisticated method that meets more specific demands.

TESTS AND SAMPLES

The tests performed on our products are divided into: 100% checked – zero defects: Tests are carried out on each panel using ultrasound waves that analyze each panel’s surface revealing the presence of defects found in its core.

SPC (Statistical process control).

Ultrasound control

The gluing of each STRATO-STOCK® panel is checked by ultrasound waves.

Ultraviolet test

UV aging test.

Sample test

The gluing of the panels is performed with internal laboratory tests.

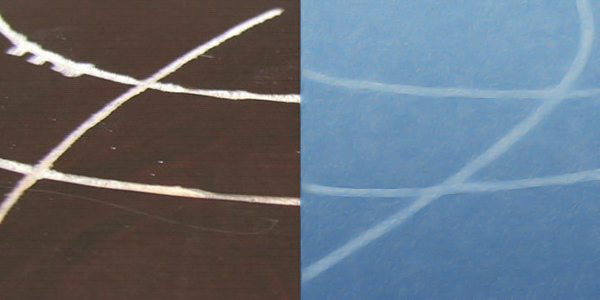

Scratch resistance

Comparison between traditional panel and film-faced plywood.

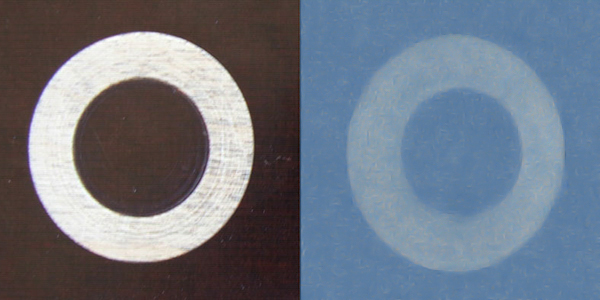

Taber test

Comparison between traditional panel and film-faced plywood.

ENVIRONMENTAL COMMITMENT

ILPA believes in a balanced and sustainable development of its economic activities that aim to preserve, protect, and improve the quality of the environment. With this in mind, our raw material of forest origin is purchased exclusively from FSC® and PEFC™ certified companies, and, therefore from forests managed with sustainability criteria and ecological, social and economic responsibility.

Production complies with designated guidelines and all chemicals used during production are in accordance with the European REACH list.

Photovoltaics

An estimated half of the electricity consumed annually is produced by a photovoltaic system on the roof of the production building.

Thermal Energy Recovery

All thermal energy generated by ILPA for its own production and heating of working premises is produced using waste products.

Recyclability of Products

Due to obvious logistical problems, the panels produced by ILPA cannot be recycled directly by the manufacturer. ILPA has however, experimented with the technical feasibility of re-using its products at the end of their life cycle.

PLAXTECH Plant

The recyclable material, after a preliminary processing phase which transforms the panel waste at the end of its life cycle into secondary raw material, has been tested using innovative technology developed by the Plaxtech company. View site