CHARACTERISTICS

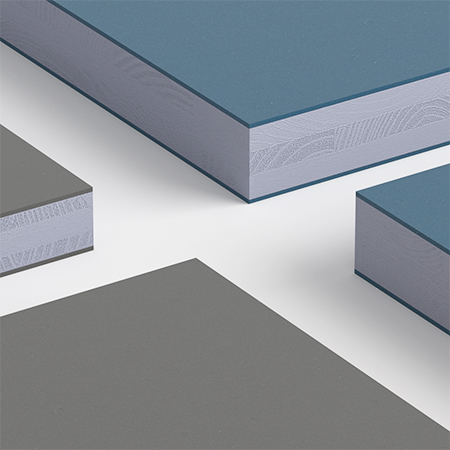

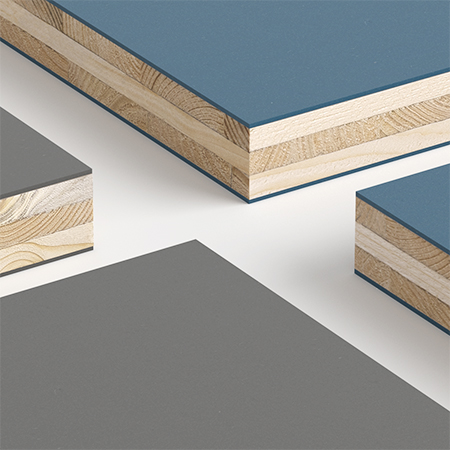

FIR-STOCK® panel is a formwork produced in 27 mm thickness, externally covered with a plastic overlay.

The polyolefin based plastic overlay allows a perfect, uniform, smooth, and impression free concrete finish, improving the result of the traditional three ply spruce panels:

- Abrasion resistance is considerably higher

- When nailed does not splinter

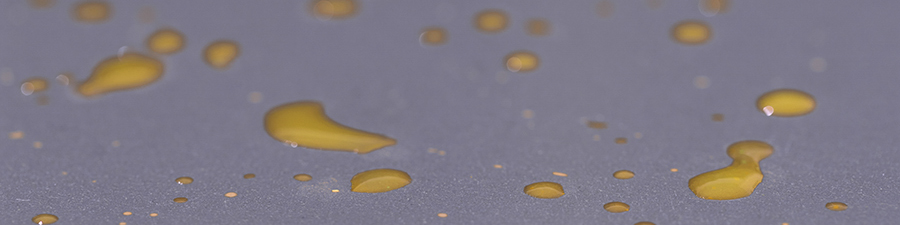

- Less release oil is needed

- Faster cleaning with high pressure water

- Panel’s lifespan increases considerably

MECHANICAL RESISTANCE

The product’s impermeability keeps the original mechanical characteristics of the wood constant over time, preventing rapid deterioration.

| Type | F / 27 | |

| Thickness | mm | 27 |

| Weight | kg/m2 | 15 |

| Bending Resistance EN 789 | MPa | 35 |

| Elastic-Modulus EN 789 | MPa | 8.500 |

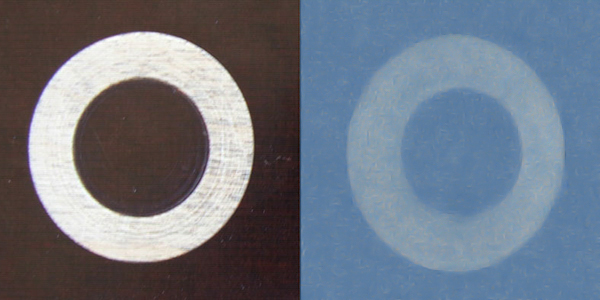

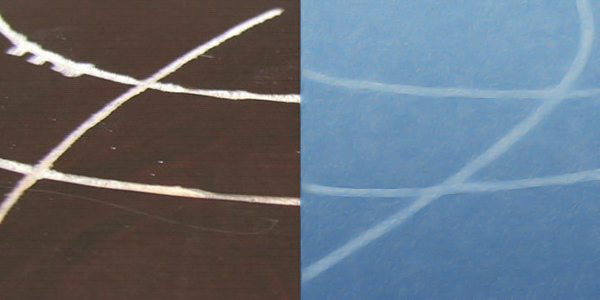

HIGH ABRASION RESISTANCE

Thanks to the plastic overlay the panel displays a high abrasion resistance.

Taber test

Scratch test

Technical Features of External Overlay

| Surface Material Water Absorption | < 3% | ISO R62 |

| Surface Hardness | SHORE D>70, GARDNER 5, JANKA 5,345 |

Catas |

| Abrasion Resistance cs17 500 g 10.000 revolutions | -0,25 g -0,14 mm | CS17 Solvay Lab. |

| Taber Abrasion Resistance | 17.000 revolutions | UNI 9115 DIN 68861/2 |

| Surface Material Burning Resistance | 23 mm/min | DIN 75200 |

| Salt Fog Resistance | The panel doesn’t show any alterations | DIN 50021 ISO9227 |

NAILABILITY

The images demonstrate the nailability of the FIR-STOCK® panel and the absence of splintering, which is common in phenolic film faced plywood.

Nail

Surface

EXCELLENT RESISTANCE TO CHEMICAL AGENTS

Thanks to its polypropylene based surface, the panel resists cement alkalis and other corroding agents.

SIZES AND STRUCTURE

The FIR-STOCK® panel can be supplied in standard dimensions, and other dimensions are available upon request.

Standard dimensions

| Code | Thickness (mm) | Internal structure | Dimension (mm) |

| F / 27 | 27 | Three Ply Spruce | 500/1000/1500 X 2000/4000 |

RECYCLABLE

The FIR-STOCK® panel consists of birch plywood core overlaid with a polyolefin based plastic sheet. A study has shown that it is possible to re-use the FIR-STOCK® panel at the end of its lifecycle. The panel, ground down with other materials, has been used as material to manufacture some products as shown below, injected with an open mold using Plastech technology (read more).

1. The panel

2. Manufacturing

3a. Example of a derivative product

3b. Example of a derivative product