THREE PLY

SHUTTERING PANEL

Concrete formwork panel with

outer melamine resin coating

Download PDF / Request information

DESCRIPTION

The three-ply panel has been produced by ILPA in Italy since 1977.

The ILPA panel, due to its structural features, is the best the market can offer today under the three-layer panels for the casting of concrete.

The surfaces of the panels undergo specialized heat treatment in order to obtain high resistances to abrasion and weather, consequently displaying a less glossy surface.

After its first use a slight warping may occur. Therefore, the second time, we recommend using the other side of each panel to restore its original straightness.

We recommend storing the panels horizontally, not slatted, and situated away from direct sunlight.

The panels can be cut to any dimensions without risking the alteration of its characteristics.

CHARATERISTICS

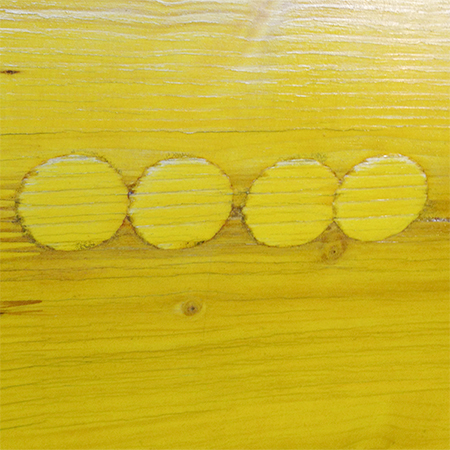

Higher resistance: Thanks to the reduced slats and lack of perimeter frame in the inner layer. Longer lasting: The melamine coating along with the addition of iron oxide allows for a stronger resistance to abrasion and exposure to atmospheric agents. Ease of cut: The absence of a perimeter frame in the inner layer allows the panel to be freely cut at any point without altering its original structure. No plugs or surface resin accumulation: our production process allows us to eliminate any traces of resin and avoid knothole plugs. Not shiny but resistant: the specialized coating used on the surface is not shiny, but has been developed to last over time and protect the panel. Best Quality/Price Ratio.

Dimensions

| Length | Width |

| 1000, 1500, 2000, 2500, 3000 | 500 |

| 3000 | 200, 250, 300, 350, 400, 450 |

| 2500, 3000, 4000 | 1500 |

Technical data

| Weight | 13,5 kg/m2 |

| Thickness | 27±0,5 mm |

| Bending Resistance EN 789 | 35 MPa |

| Elastic-Modulus EN 789 | 8.500 MPa |

COMPARISON

Competitor 1a

Competitor 1b